CGM 125 Export CH Piano Stool

Price on application

With a wide variety of customizable features on offer, CGM allow you to build your own unique high-quality piano stool. Refer to the catalogues in the description below to choose your own colour, wood, finish, padding, coating, mechanism type and more. Contact us with your choice or to request further information. Our team would happily advise you on the creation of your ideal stool.

Detailed Description

CGM Product Sheet

You can customize the features of your CGM 125 Export CH piano stool to your liking. Click on the links below to browse the wide range of design options available.

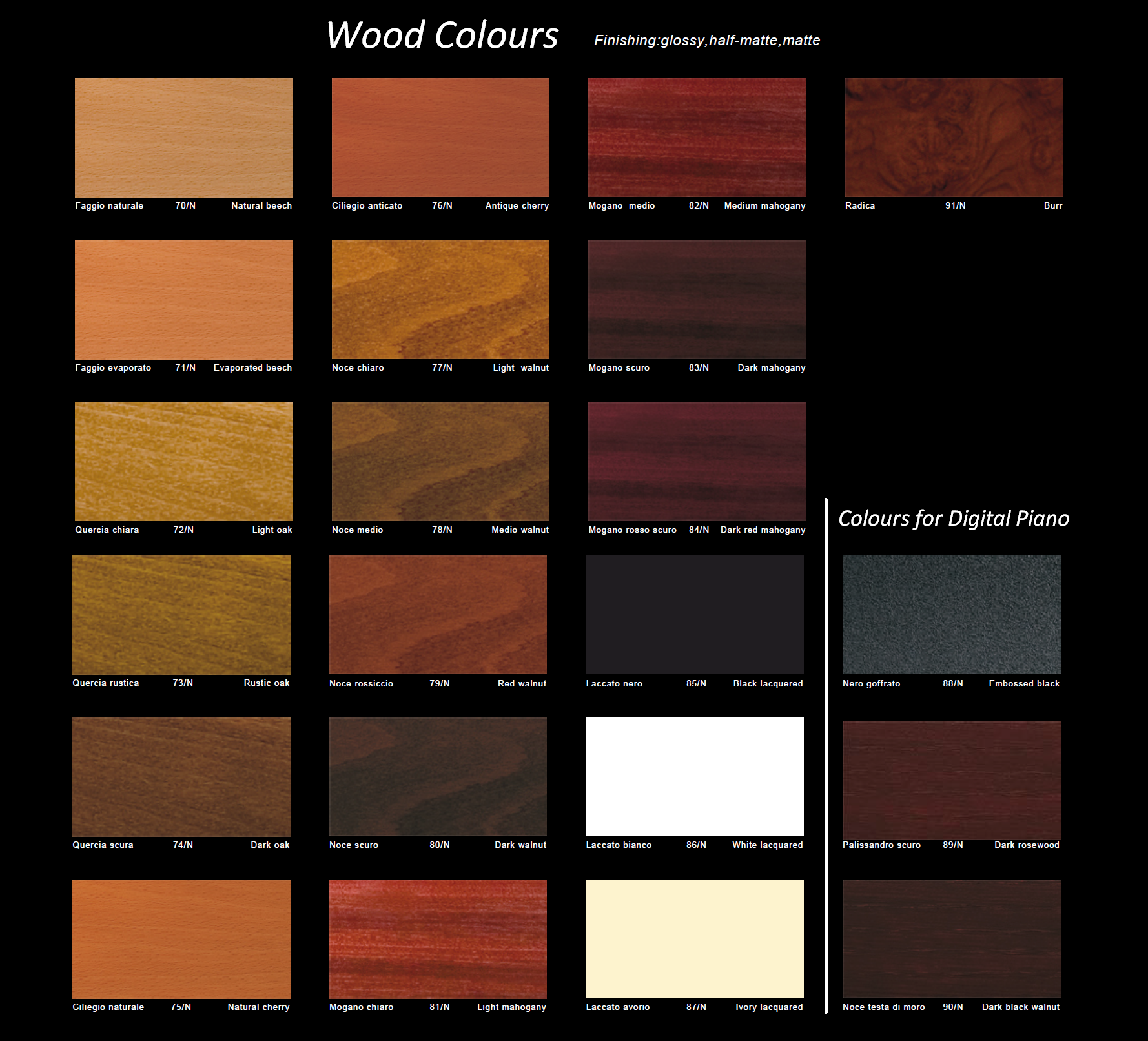

WOODEN STRUCTURES

- Solid beech and on request: solid walnut, oak, ash, mahogany and rosewood.

- Solid veneered beech with commercial essences.

- Choose your perfect colour and wood type from this catalogue.

HEIGHT ADJUSTMENT MECHANISM

- Right/left metric screw and construction steel bushings S355JR

- Construction steel pantograph and support plates S355JR

- Screw adjustment stool in construction steel S355JR

- Aluminum stool bush

- Painting of the pantograph with epoxy powders

- For more information on which adjustment mechanism suits your needs, click here.

SITTING

- Padding material: polyurethane foam with variable thicknesses and densities. On request no fire polyurethane foam, CLASS 1 / TB117

- Panel material: birch or melamine plywood

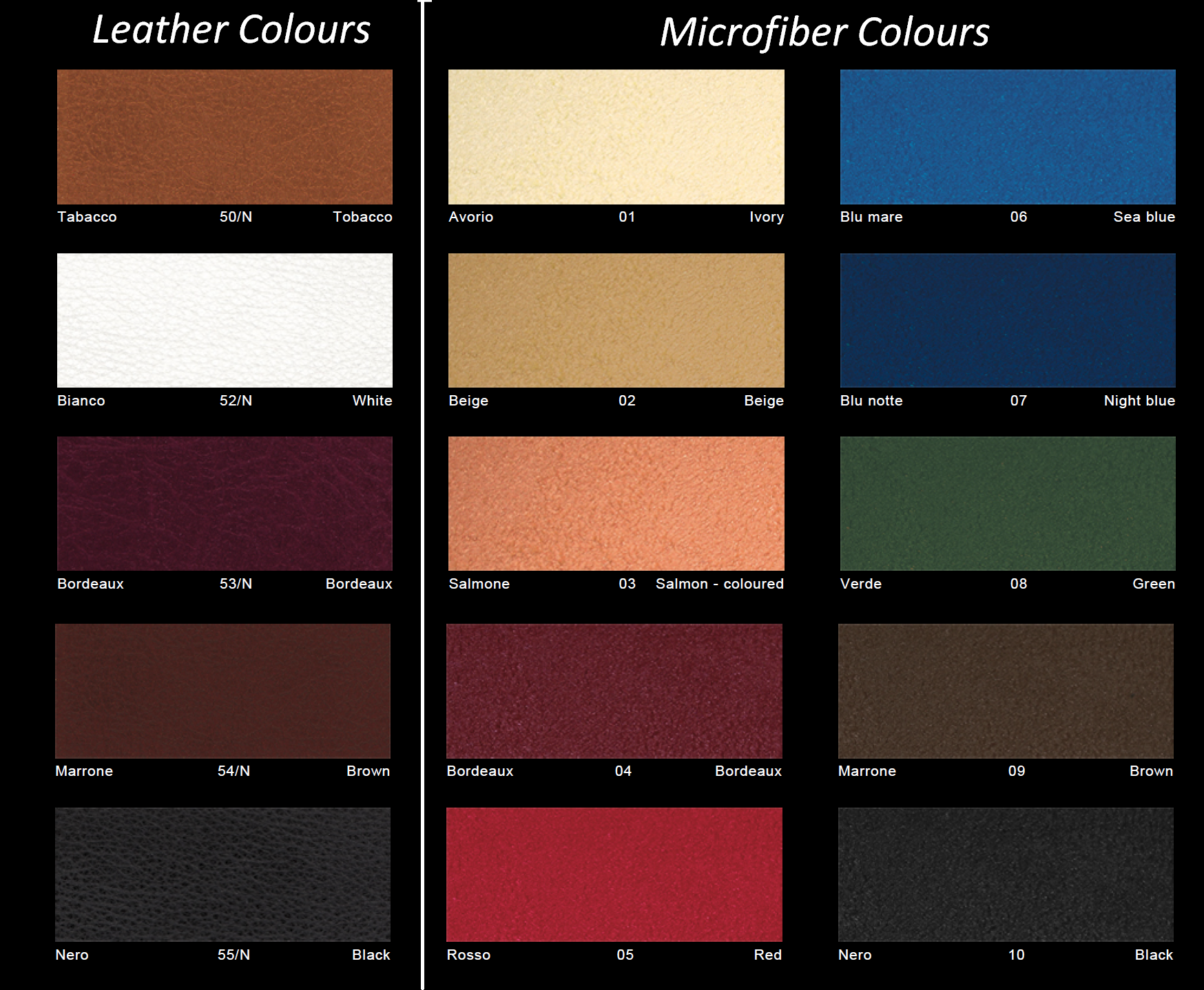

Cover material:

- Imitation leather ( PVC 27% – PU 54% CO 19% )

- Microfiber ( PL FR 100% )

- Velvet ( PC 44% – CO 40% – VI 8% – PL 8% )

- Leather: bovine leather from European and no-European abattoirs. Chrome tanned, aniline water dye with pigments

- Select your desired cover material and colour from this catalogue.

ADJUSTABLE FEET

- Gilded iron

- PVC

PAINTING

- Non-conveyed water colors

- Spray with two-component polyurethane, acrylic and polyester resins

- Glossy finish: shine 95/100 gloss

- Half matt finish : 65 gloss

- Matt finish: 10/15 gloss

- Embossed finish: nonglare 0 gloss

Customizable finish glossy on request.

CLEANING AND MAINTENANCE

It is advisable to lubricate the contact points between the threaded rod, support plates and threaded bushing.

For daily cleaning, use microfiber cloths with water and neutral detergents.